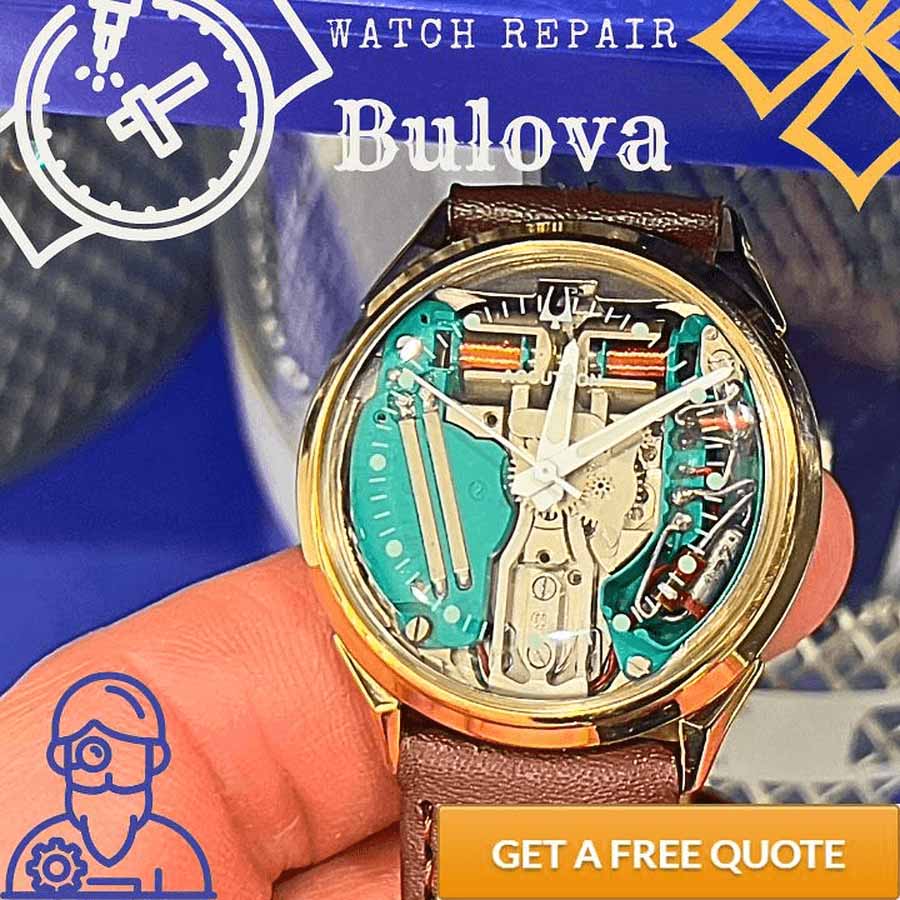

Fixing Up a Classic: The Bulova Spaceview Cal. 214

There’s something really cool about old watches, and the Bulova Spaceview Cal. 214 is a great example. I’ve worked on a lot of watches, but recently I got to have a go at this one. It’s a classic watch, known for its tuning fork technology. That being said, working on older watches like this can throw up a few challenges.

Vintage watches, such as the Bulova Spaceview Cal. 214, are incredibly special. After working on several timepieces, I had the opportunity to take a crack at this one. With its tuning fork mechanism, this classic watch can present a few problems. Nevertheless, it’s truly an amazing feature piece.

Becoming acquainted with Accutron Cal. 214

I had to become familiar with the watch based on repairing those in the past. The Accutron 214 is not like the conventional mechanical watch – it has a tuning fork that is electric. That made it quite popular in its time. As I took it apart, it was unmistakable how essential each component was. It was important to be cautious when handling anything, from the coil system to the index wheel, to make sure it would be operational after reassembling.

Restoring the Time-Resistant Accutron 214

Rebuilding the Accutron 214 was a painstaking practice, showing the watch’s intricate structure. All elements, from the index wheel to the cell coils wheel and wire arrangement, had a precise spot and purpose. Being careful with each part was essential to guarantee the reconstructed watch worked as intended. Considering the creation, it was evident why the Accutron 214 was greatly coveted – its extraordinary electric system truly stands out.

Reviving the Bulova Spaceview Cal. 214 was an immensely satisfying experience.

For this repair, the watch movement required a thorough cleaning and repair of the coils using conductive adhesive. This was no simple task, as the watch was a vintage piece and the parts were delicate and fragile. The first step was to disassemble the watch movement and remove each individual piece. Once all the pieces were removed, I carefully cleaned each one with a soft brush and a special watchmaking solvent. I took extra care to make sure that I didn’t damage any of the delicate parts, as they are essential for the watch to work properly. I then inspected each component carefully, especially the teeth on the index wheel, ensuring that the tiny pivots and gears were all in place, as well as ensuring that the delicate electronic circuit cell coils. I checked for any signs of wear and tear, as even the slightest damage could cause the watch to malfunction. After the cleaning process and application of the conductive adhesive to the cells, the watch started to hum.

I Need Help with my Bulova Watch

I had to use a variety of tools and techniques to repair the timepiece. I started by taking it apart, piece by piece, and examining each component to determine what needed to be done. I had to use a set of small tools, including tweezers, a magnifying glass, and a screwdriver, to complete the task. I had to be very precise and careful with my movements, as even the slightest mistake could have caused irreparable damage especially to the index wheel or the cell coil assembly. I had to use the tweezers to delicately remove the small screws that held the module together, repair the coils and assemble them back together. As soon as I heard the hum and saw the hands rotate, I knew I had been successful. Not only was it a watch, but it was a part of American watchmaking tradition. Working on it was a fantastic opportunity and it was gratifying to extend the life of a traditional timepiece. It was a great honor to be able to work on something so steeped in history and craftsmanship, and I felt a sense of pride every time I worked on it.

I love the feeling of taking something that is seemingly broken and bringing it back to life. It’s like a little puzzle that you have to figure out, and when you finally do, it’s a great feeling of accomplishment.

our workshop in numbers